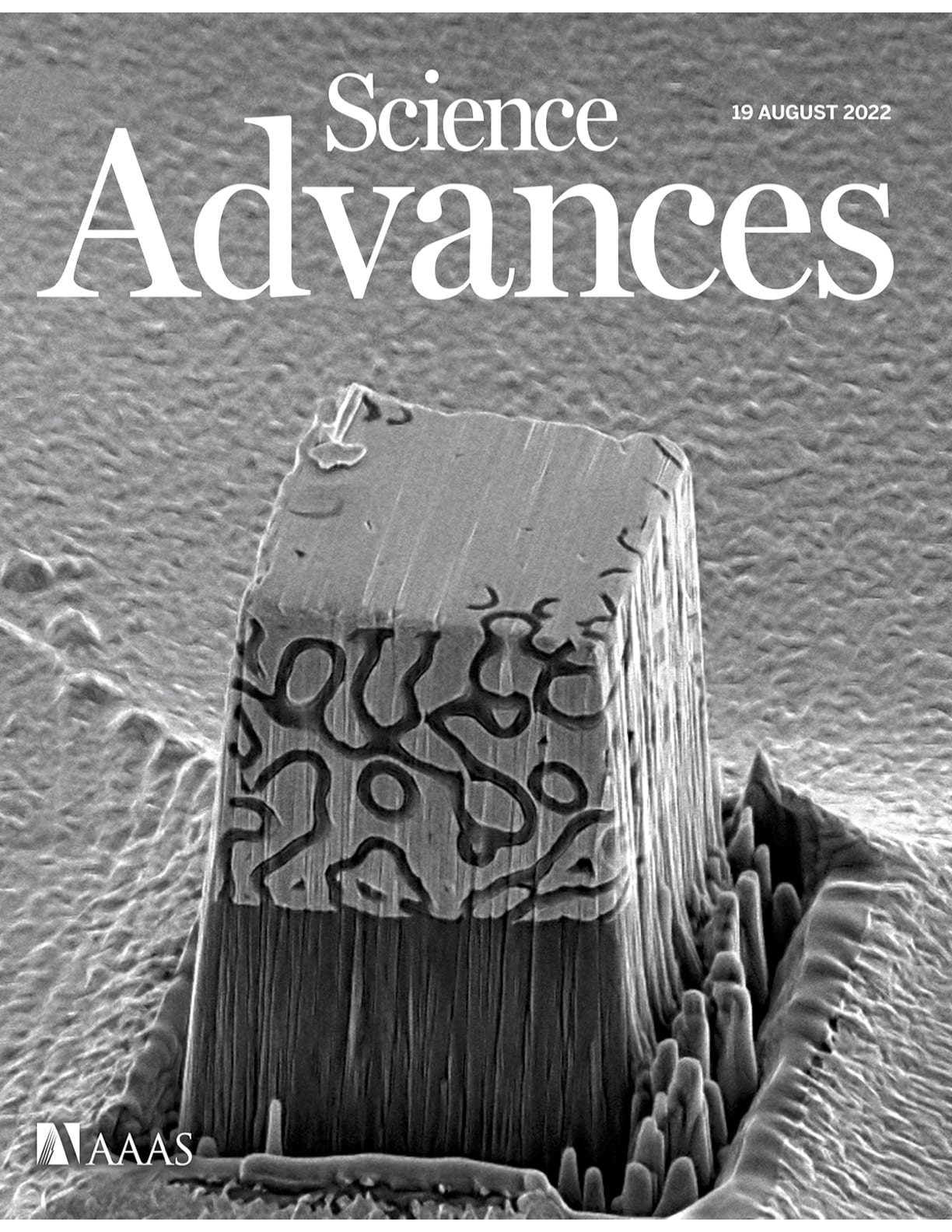

UCI engineers push nanostructure properties to new extremes

Applications for strong and lightweight materials range from aviation to medical implants

Researchers at UCI have greatly increased the strength and energy absorption properties of nano-architected structures – already recognized for their robust and lightweight qualities – by fabricating interpenetrating phased composites. In a paper published recently in Science Advances, the researchers in the Samueli School of Engineering describe how their continuous architectures of three-dimensionally printed carbon shells and matrices of nickel outperform traditional carbon-based nanolattices and even bulk mono-materials.

“The nano-architected nickel and carbon IPCs created by our team achieved an unprecedented combination of compressive strength, energy absorption and compressive deformability in our testing,” said senior co-author Lorenzo Valdevit, UCI professor of materials science and engineering and mechanical and aerospace engineering. “Our materials achieve exceptional combinations of strength and ductility and introduce a new design approach for impact-resistant structures.”

Valdevit said that while his team’s work on this project used nickel for the metallic phase, lighter metals such as aluminum may be employed, potentially further improving the strength to weight ratio.

“The IPC-based structures introduced in this work constitute a major advancement in the field of nano-architected materials, providing important groundwork for widespread research efforts across different disciplines throughout materials science,” said first-author Jens Bauer, former research scientist in Valdevit’s group and currently research group leader at the Karlsruhe Institute of Technology in Germany.

UCI former Ph.D. student Sala-Casanovas and current Ph.D. student Amiri also participated in the study. The project was funded the Office of Naval Research and the Army Research Laboratory and was conducted entirely at UCI, party in facilities provided by the UC Irvine Materials Research Institute.