Clean and green: UCI physicist helps invent novel way of converting nitrogen to ammonia

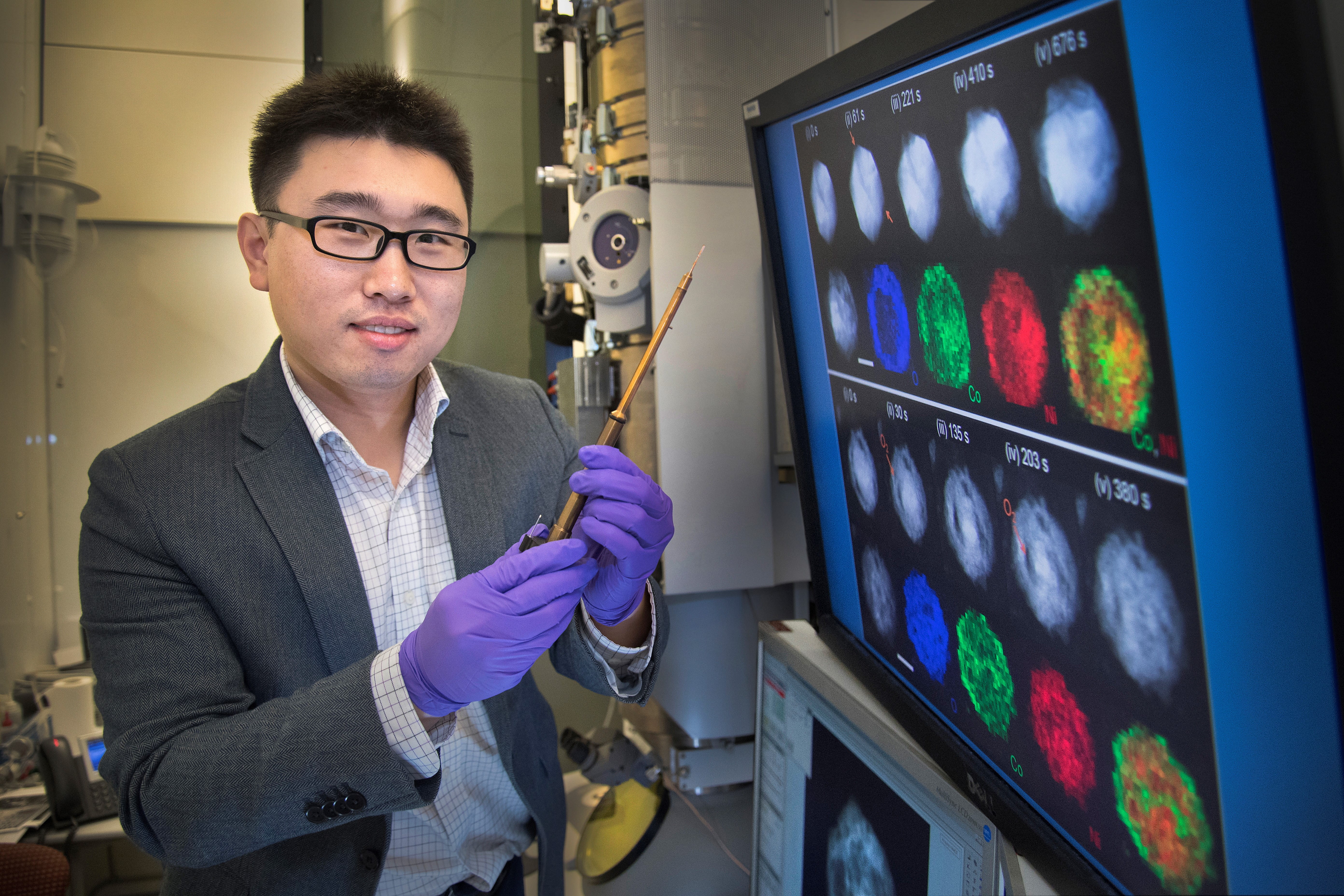

The ammonia you use to clean and disinfect your kitchen floor starts off as nitrogen, a gas that makes up almost 80 percent of Earth’s atmosphere. But the conversion requires the breaking of a strong triple-chemical bond in a high-heat, high-pressure industrial process. UCI physicist Huolin Xin worked with his colleagues at Brookhaven National Laboratory to come up with a new, more sustainable way of producing ammonia, which is also a key ingredient in crop fertilizers. Their technique uses atomically dispersed molybdenum, a readily available metal, as a catalyst to electrochemically convert nitrogen to ammonia at room temperature and atmospheric pressure. The key seems to be anchoring single molybdenum atoms in a nitrogen-coordinated environment in their experiments. “In nature, bacteria convert nitrogen gas to ammonia with the nitrogenase enzyme, the active center of which is molybdenum, an abundant, nonprecious metal,” said Xin, now a UCI assistant professor of physics & astronomy. “By also relying on this element in our electrochemical conversion, we mimic this biological nitrogen fixation process and are able to more cleanly and sustainably produce ammonia.” He noted that the current method of producing ammonia, which has been in existence since the early 1900s, consumes massive amounts of energy and emits significant quantities of carbon dioxide to the atmosphere. If future manufacturers were able to use electrolyzing cells and cheap metal catalysts, he said, they could potentially create a valuable commodity with renewable solar or wind power. A paper describing the process invented by Xin and his colleagues was published today in the journal Angewandte Chemie.