UCI team initiates effort to build ‘bridge' ventilators

Quick-to-produce devices could help alleviate hospital shortages during COVID-19 crisis

The call has gone out: Overtaxed hospitals need more ventilators for the growing number of COVID-19 patients. And a UCI School of Medicine team is working with corporate and university collaborators around the country to help provide them.

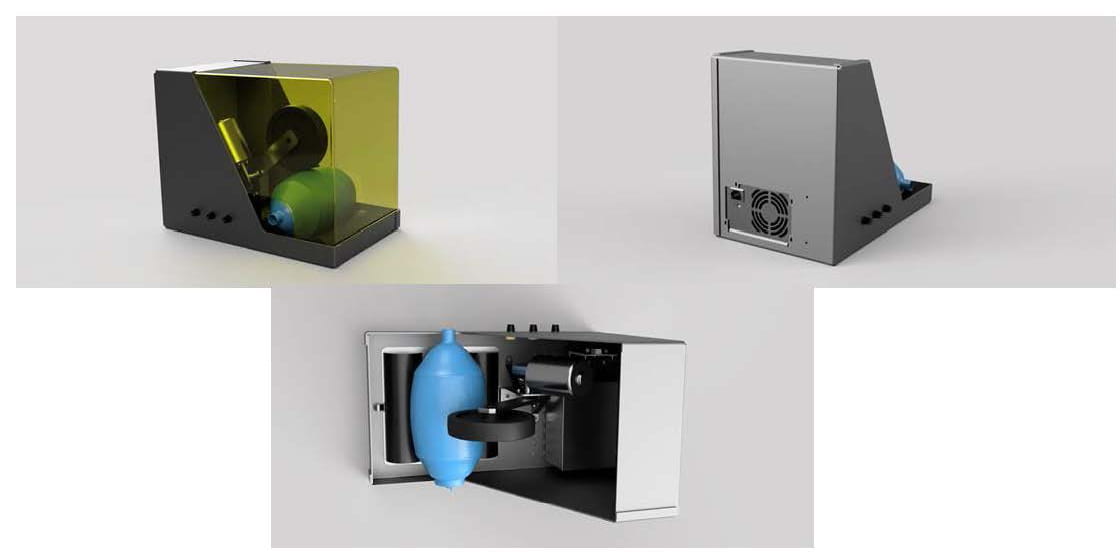

UCI surgeon Brian Wong and anesthesiologist Govind Rajan are partnering with Tom Milner, acting director of the Beckman Laser Institute & Medical Clinic, to conceive and drive the design and creation of what they call a “bridge” ventilator. It’s an inexpensive, quick-to-manufacture device to be employed when intensive care units are overwhelmed and no standard ICU ventilators are available for patients undergoing respiratory failure.

“The need for ventilators is a medical Dunkirk,” Wong says. “It’s a once-in-a-generation call to arms that we all must respond to. Our designs are different. We’re building ‘bridge’ devices that can be easily made to serve as stopgaps when medical-grade ventilators are not in full supply.”

In simple terms, these bridge ventilators replace human-operated “bag valve masks,” low-cost, widely available ambulance staples used to manually ventilate patients. The version the UCI team conceived has a mechanical attachment that automates the pumping function. Here’s a video of an early prototype:

To accelerate the design and construction of their device, the UCI team has established the Bridge Ventilator Consortium, which includes engineers and business consultants from the University of Texas, Virgin Orbit and Medline Industries.

The prototype that’s moving into the manufacturing phase was designed and built by Milner’s lab at UT Austin (where he currently has a faculty appointment in engineering), in collaboration with UCI clinicians and biomedical and mechanical engineers.

The ventilator is constructed from industrial components that are extremely reliable. It doesn’t have all the bells and whistles of a conventional medical ventilator (the core of the prototype, for instance, is a Toyota windshield wiper motor) but will have the minimum safety profile for regulatory approval.

“We have put the system through rigorous testing,” Milner says. “We are now pursuing regulatory review by the U.S. Food and Drug Administration, and if all goes well, our ventilator will be ready for production very soon.”

In light of the COVID-19 pandemic, the FDA recently streamlined the regulatory process for new devices such as the UCI bridge ventilator.

Milner adds that the FDA-approved design will be freely available to all manufacturers and that the Bridge Ventilator Consortium is in discussions with several companies to produce the units. Virgin Orbit has already committed to making a version of them.

In addition, representatives from the states of California, Hawaii and New York have reached out to learn more about accessing the bridge ventilators.

“While UCI has become the incubator for this project, what’s remarkable is that almost everyone – engineers, physicians, industry leaders – is opting into this consortium as volunteers and freely sharing intellectual property,” Wong says. “This is 100 percent open source for the public’s benefit. It’s a gathering of smart, selfless, well-intentioned people. And it’s actually no surprise that UCI has become the hub, as we have a proud tradition of collaboration and innovation.”